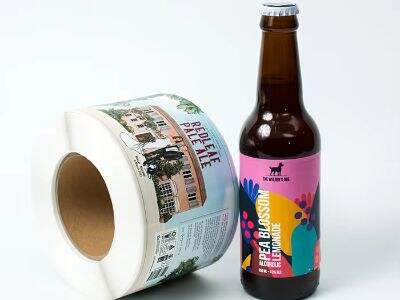

Stickers staying stuck to drink bottles can be tricky at times. Bottles get wet or cold, and they are jostled quite a bit, and if the label isn’t right it can peel off inside of no time. At OPT, we understand that labels do not come off. If the adhesive it uses is lousy, or if you choose the wrong label material, your bottle will not look its best. This can cause half of customers to assume the drink inside is no good. So, the choice of a label and glue is crucial. It’s not just sticking a sticker on; it’s choosing materials and adhesives that get along. When applied properly, the label remains snug and attractive, even after hours spent chilling in the fridge or bouncing around inside delivery trucks. We’ll discuss the best sources for good labels in bulk, and which materials help get labels to stay on longer trouble-free

Where to Find Quality Adhesive Labels for Mass Bulk Beverage Bottle Orders

It isn’t easy to find the best place to buy a lot of labels. You want labels that won’t come off, even after bottles go through wet or cold. Opt has the best adhesive label for bulk orders. Why? That's why we ensure that all labels feature a glue that works perfectly for glass, plastic, or metal bottles. Some are more effective on smooth bottles, some work on textured. And the climate where the bottles are stored makes a difference, hot places would require different glue than cold ones. At OPT, we think about this stuff. Mass orders require special focus, for if even a few labels fall off it can cause big trouble in stores. Multiply that by the thousands of bottles on shelves with parts of their labels missing, it’s messy and cheap. We advise companies on the right label with glue formulas that stay sticky through cold storage, moisture and rough handling. In addition to adhesive, the size and shape of a label matter in how well it sticks. Larger labels may require stronger glue; curved bottles may call for flexible labels that can bend without cracking or peeling. Each batch of labels is put through rigorous factory inspection to ensure high quality. We also suggest that customers place an order for samples first, so they can see and feel the label on their bottles, and check to see how the glue performs in actual use. This is a money saver and headache preventer later. Bulk covers from OPT are also guaranteed for stickiness and longevity. And we can match orders to special requirements, as with waterproof or heat-resistant labels. So, if you’re ordering a lot of labels, be sure to use a company like OPT that understands the obstacles and provides labels that are stable no matter what

Good Material for Beverage Bottles Specification

As with the glue, label material matters. If the label is paper that goes to mush when it’s wet, it will peel quickly. Plastic labels, such as BOPP or vinyl, are more durable and hold up to water and cold better. OPT learned this through years of experience. For drinks that will be stored in the fridge or freezer, plastic labels last longer and won’t let their print get smeared. Paper labels are an option, as well, but they require specialized coatings to be resistant to moisture. Labels must also resist oils or alcohol sometimes, depending on what the beverage inside is. It’s why choosing the right material is never one-size-fits-all. If the bottle is glass and cold, a seamless plastic label held in place with powerful adhesive could be a good idea. Cheaper paper labels are probably still fine for one-time bottles, as long as you won’t get the bottle too wet or handle it too much. With OPT, customers can choose label materials that are tailored to the drink. A juice bottle that enters cold storage, for example, could receive a plastic label with a matte finish to reduce glare. A bottle for sparkling water sales might look best with clear labels that allow the bottle’s design to shine through but still adhere to its surface. And sometimes, labels need to contort around sharp curves. Flexible materials are better in these situations. Produce name prints, bar codes and graphic images that are clear and easy-to-read with the same long-service life of your labels. We have watched labels drop off anyway as companies choose cheap materials without considering what the bottle’s environment is going to be. That’s frustrating and costly. OPT recommends considering where the bottle will be stored, how it will be treated and what look you want for the labeling. Then select a material that can endure all of this. It's always smart to test sample on the actual bottles before full production. That way you don’t get any surprises, like labels curling (up or) colors washing out. Offered in the right label material, this bottle looks great and helps your product stand out on the shelf. This is a good time to spend some time and care inasmuch that the better your label looks, the more professional it will make your drink look, and ultimately feel for customers

Common Mis-Adhesion Problems in Beverage Labels and How to Correct

You shouldn’t have to worry about the label on your juice or soda bottle peeling away and looking cruddy. But labels can also peel off or get damaged sometimes. This occurs due to a couple of the standard issues regarding label adhesion on beverage bottles. One big problem is moisture. Bottles are often waterlogged, or, if they are cold, sweat. If water seeps between the label and bottle, the glue can lose its adhesive grip on the label, causing it to slide off. Another issue is surface of the bottle. Some water bottles are constructed of smooth plastic, glass or metal. Every surface requires its own specific kind of glue or label material to adhere successfully. If the glue doesn’t look right with the bottle surface, it could slip off. Temperature also plays a role. If bottles move from cold to warm environments, the glue can become weak or too soft and the label will peel off. The bottle may have an accumulation of dust or oil which prevents the glue from adhering properly when being labeled

In order to try and eliminate these issues, OPT advise surface cleaning the bottles before the labels are applied. Dust, oil and moisture make it harder for glue to adhere. it's important to have the correct adhesive. OPT provides developing special adhesives that can work for different bottle material and in different temperature. For instance, some adhesives excel on cold bottles out of the fridge; others are designed to remain tacky even if bottles get wet. Using materials that repel water and prevent scratches is one solution, to ensure the label remains clear and bright. Plus, applying labels in clean, controlled locations minimizes the risk of letting dust or moisture inside. By following these steps and choosing the right products, beverage companies can ensure their labels stay on the bottles and look good from factory to retail

How Do You Properly Label Bottles of Beverages in a Bulk-Education Setting

When making thousands of beverage bottles for stores, labelling has a crucial role. When the labels peel or are unattractive, it can make the products look low quality. OPT understands that attentive and detailed labeling allows companies to keep their customers smiling - and sell more drinks! One of better performing practice we found was to constrain the environment in which labels are emitted. Maintaining a dry, clean and the right temperature helps labels adhere better. Then air-borne dust or moisture does all manner of mischief. Second, bottles must be cleaned prior to labelling. That’s wiped down, as in any dust, oil or water that will interfere with the glue having a good day. Machines can slap on labels in big factories, fast. These machines have to be set up just so each label goes on straight and smooth, no bubbles or wrinkles, please. OPT supplies instructions on how to tailor machines to unique bottle shapes and sizes in order to achieve perfect results every time

Another useful tip is to apply adhesives and label materials that are compatible with the surface finish of the bottle. OPT’s broad selection of adhesives allow companies to select the most appropriate glue for glass, plastic or metal containers. In addition, labels must be tested for full production run. Small tests can confirm whether the labels adhere well during shipping and storage. If a label fails the test, modifications can be made before time and money is wasted. And lastly, it's nice to store those labeled bottles in a tasteful manner. Storing them in a cool, dry environment minimizes the risk of damage to labels before goods are delivered to customers. By adhering to these hydrating mascaras best practices, wholesale producers can make sure their beverage bottles appear professional and keep their labels stuck making the entity of their drinks pop in stores

What are the current trends of adhesive labels on beverage bottles in wholesale markets

Opt knows the world of beverage bottle labels is always evolving; it’s constantly in-tune to the latest trends. One major trend is to use earth-friendly labels and adhesives. More firms want to have a green image, so they choose the used of recycled or biodegradable materials. OPT provides special adhesives that can adhere well to these green materials, but still have a high stickiness to bottles. Another trend is smart labels. These labels can come equipped with special features like QR codes or NFC chips that shoppers scan with their phones. That way, you can easily share information about the drink, such as its ingredients or place of origin. OPT helps companies make labels that function in concert with this technology and yet still stay securely on bottles

The third trend is that of the labels on wines becoming more interesting, both in terms of how they look and feel. Instead of drab paper labels, beverage companies increasingly use clear or textured inks, as well as metallics to grab the shopper’s attention. The adhesives of OPT are made to adhere securely to these special substrates regardless if the bottle surface is smooth or has some sort of round. Last but not least, is the increasing requirements for labels that can withstand harsh environments. Some beverages are kept cold, others frozen; some heated. OPT’s newest adhesives are formulated to remain tacky in these conditions, so the label won’t strip or fade. These trends illustrate how the label industry itself is advancing, to better serve beverage companies in making their products more aesthetic and consumer-friendly as well as eco-friendly. OPT has the expertise to allow businesses to stay on top of these changes and always ensure their labels remain in place and appear fantastic

Table of Contents

- Where to Find Quality Adhesive Labels for Mass Bulk Beverage Bottle Orders

- Good Material for Beverage Bottles Specification

- Common Mis-Adhesion Problems in Beverage Labels and How to Correct

- How Do You Properly Label Bottles of Beverages in a Bulk-Education Setting

- What are the current trends of adhesive labels on beverage bottles in wholesale markets